Find out how our new crop of CEOs Who "Get it" keep their organizations' workers safe. Then, learn more about some of the safety product and service vendors who are in business to help keep your workers safe.

Responding is Nancy Sabin, product marketing manager, Shawmut Corp., Plymouth Township, MI. Material Spunbond

To understand how filter media works, we first need to know what it is.

For an N95 filtering facepiece respirator, the filter media is the middle layer of material that’s sandwiched between the outer layer of spunbond material and the inner shell that’s sealed to the user’s face. Typically, the inner layer provides shape or support for the FFR, while the outer layer helps to protect the filter media.

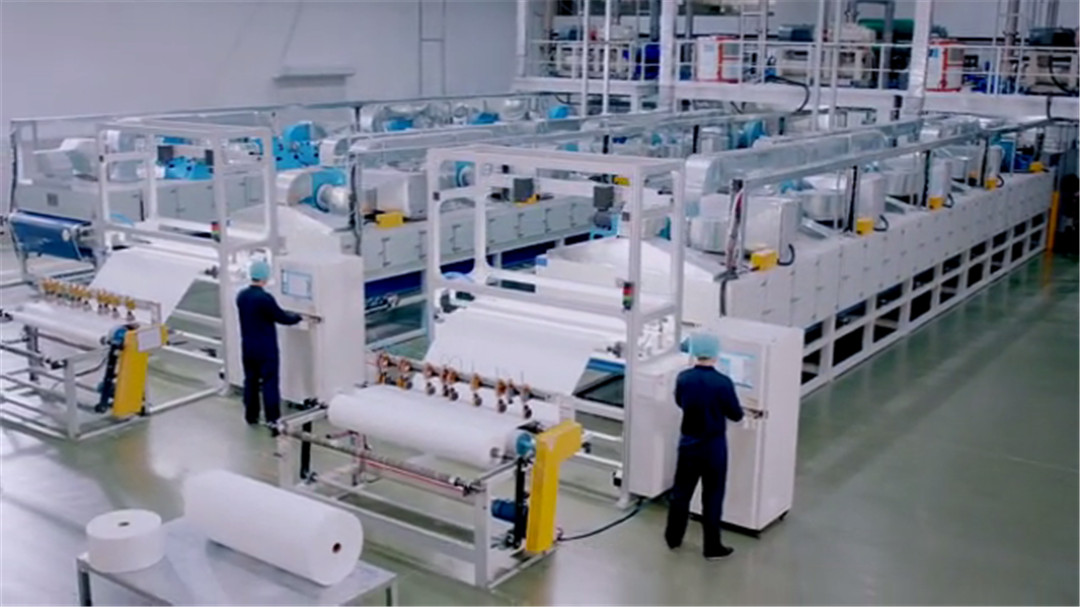

When it comes to material, filter media is synonymous with the term “meltblown.” Meltblown is a nonwoven material that’s manufactured by changing polymers from a solid substance into microfilaments. This is accomplished by converting a powdered version of the polymer into a flat, solid mass by using heat. During this process, the fibers are randomly tangled and joined together to create the filter media. The result is a porous material that allows air to flow through when an FFR is in use.

Particles are captured by the filter media from the processes of diffusion, interception and impaction. The smaller particles move in a random motion (diffusion), increasing the probability of being captured by a fiber. The larger particles have enough inertia to overcome the airflow path and follow a straighter path, colliding with the fibers (impaction). The most penetrating particles, 0.1 to 0.3 microns in size, are captured from interception and impaction. Particles in this size range are the most likely to be able to follow the airflow around the fibers.

In addition to capturing particles through diffusion, interception and impaction, the meltblown is electro-magnetically charged. In the production process, an electrostatic charge is applied to the filter media. This treatment then creates a charge to the material, which forms an electrostatic attraction toward the charged particulates, including dust.

The function of the FFR is to filter out at least 95% of the most penetrating particles that are neutralized. This will ensure particles such as dust, pollens, smoke, bacteria and viruses are filtered out. Basically, the material’s job is to keep as many particles on the outside of the FFR as possible to maintain a 95% efficiency rating.

When particulates are pulled toward the FFR, they attach themselves to the material as the user is breathing in. Not only do they attach to the outer layer, but they also become trapped in the tiny gaps that are created in the meltblown production process. When the user exhales, the positively charged particles remain attached to the FFR. The filter media in the FFR acts like a magnet so the particulates hang on and don’t let go.

When wearing an FFR, you want to be comfortable and not have any restrictions when you breathe. When the FFR user draws in breath, air flows through the material. As the user exhales, their breath should easily flow back through. The action of inhaling and exhaling through material is referred to as breathability. The more breathable the material, the more comfortable the FFR will be while in use.

In the end, the goal of the filter media is to allow the FFR to work as it designed to do so. The FFR should filter the air and not hinder the user’s breathing. It should protect the user from contaminants without restricting airflow. To ensure the N95 works efficiently, it must also fit and be worn properly – each time one is needed to protect the user.

Editor's note: This article represents the independent views of the author and should not be construed as a National Safety Council endorsement.

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)

Take a quiz about this issue of the magazine and earn recertification points from the Board of Certified Safety Professionals.

Read what other people are saying and post your own comment.

Personal Protective Equipment (PPE): Providing PPE and Ensuring Its Use

OSHA Inspections: Are You Prepared?

OSHA Record Keeping and Reporting Cheat Sheet

Safety Lessons Around the World

Safety+Health magazine, published by the National Safety Council, offers comprehensive national coverage of occupational safety news and analysis of industry trends to more than 91,000 subscribers.

Burlap Weed Barrier Save lives, from the workplace to anyplace. The National Safety Council is America’s leading nonprofit safety advocate. We focus on eliminating the leading causes of preventable injuries and deaths.